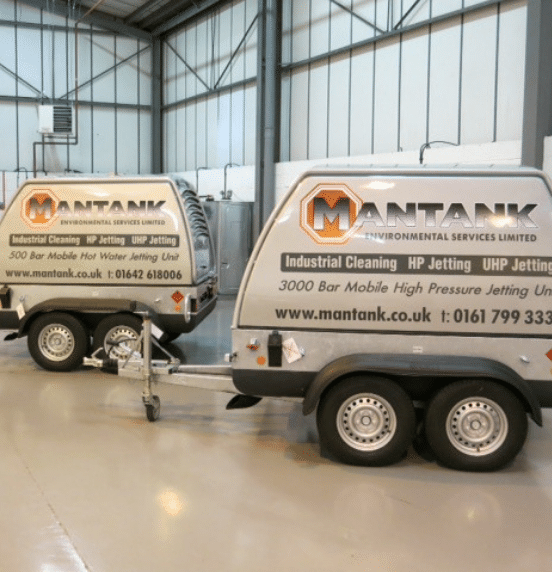

Professional UHP Jetting Services

The jetting techniques we utilise:

-High pressure and medium volume (HP)

-Ultra-high pressure and low volume (UHP)

We provide cost-effective options for the deep cleaning of a high range of surfaces and vessel types.

The combination of these two techniques allows us to make sure that there is as little impact as possible on the environment and the surrounding areas. After all, the last thing you want from water jetting is unnecessary damages.

Water Jetting

at Mantankk

At Mantank, we offer professional water jetting to all of our customers who need it. In fact, we’re proud to be a valued member of the Water Jetting Association. Whether it’s a small project or one that’s much larger, we’re able to tailor our water jetting services to meet your needs. With our varied water jetting service, there’s no project too big or too small. To find out more about water jetting or any of our other services – get in touch! Contact the Mantank team today on 0161 799 3337 or 01642 618006 and speak to an expert. Alternatively, get in touch via the online contact form.

We have locations across the UK

We have depots across the UK get in touch for a free no obligation quote

Latest News & Articles

22 March 2024

In the face of escalating environmental challenges, including climate change and rapid urbanisation, the...

8 March 2024

In today’s environmentally conscious world, the demand for effective environmental clean-up services has never...

1 March 2024

Water tanks are crucial components of both residential and commercial water systems, providing a...